Products Filter

3 Categories

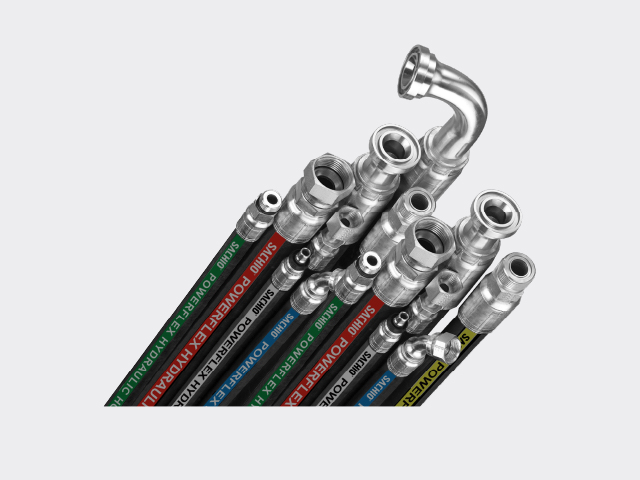

Hydraulics systems convert pressurized oil into mechanical energy. Hydraulic accumulators store pressurized hydraulic fluid and release it as needed to maintain steady pump flow and pressure, dampen vibrations and shocks, and compensate for leaks or thermal expansion in the system. Hydraulic cylinders are linear actuators that provide back-and-forth movement when they are under pressure. Hydraulic equipment replacement parts keep hydraulic systems working, prevent failure, and reduce downtime. Hydraulic filtration reduces normal wear by removing contaminants introduced into the system. Hydraulic fittings securely connect high pressure components used to create a hydraulic system. Hydraulic hose crimping machines press hydraulic fittings onto a length of bulk hydraulic hose to create custom assemblies. Hydraulic motors create mechanical energy from a hydraulic power unit. Hydraulic oil coolers remove heat from hydraulic systems with air or water heat exchangers. Hydraulic tools use fluid pressure for smoother performance and higher force than air- or electric-powered tools. Hydraulic power units pressurize oil to power hydraulic motors used in lifts, tools, and equipment. Hydraulic pumps circulate or transfer hydraulic fluids to tools and machinery. Hydraulic rams apply large amounts of linear force needed for pressing, spreading, and load-supporting applications. Hydraulic tanks hold excess hydraulic fluid as the volume of oil used by a system changes. manage fluid flow in hydraulic systems.